Masten

Masten Landing a spacecraft on the lunar surface is tricky. As any engineer can tell you, dust doesn't help.

A regolith, billions of grains of crushed rock are kicked up during a rocket-assisted landing, a huge impediment to creating reliable, reusable landers. Dust is also a notorious killer of robots, which is a critical issue for the future of space exploration and commercialization. Compounding the problem, commercial missions currently in the conceptual phase are more sophisticated than previous lunar missions, and the size of the lunar landers and the power of their engines has grown. That's only going to make the problem of space dust, which can rip through the sheathing and clog engines and instruments, that much worse.

One solution is to build landing pads on the moon, but that's incredibly expensive ($120 million per pad, according to one estimate). An alternative may be to use a lander's descent to create a landing pad in real-time.

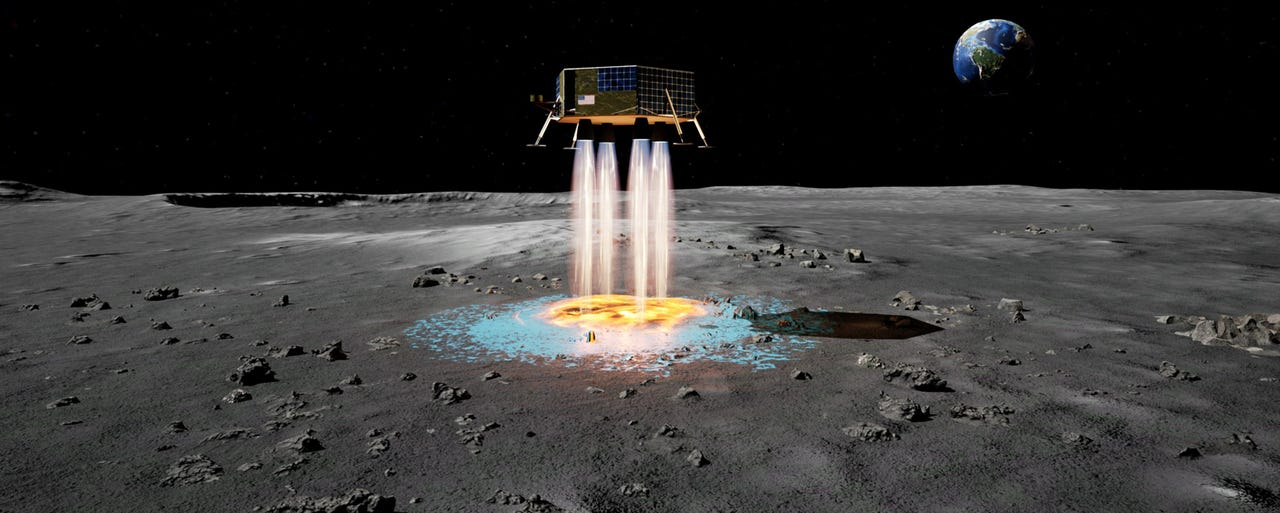

That's just what a company called Masten Space Systems, which we've been tracking on ZDNet, is testing. The idea is to create near-instantaneous landing pads by injecting ceramic particles into rocket plumes to form a coating over lunar regolith as a lander descends on the lunar surface. It's a bit like giving the lander a Midas touch -- only a ceramic touch -- and it could significantly reduce dust issues for future missions.

The presto-landing pad concept is called the in-Flight Alumina Spray Technique (FAST), and the company has been testing it for several months with positive results.

"Following our Phase 1 NASA Innovative Advanced Concepts award, we've spent the last year studying and advancing the FAST concept in collaboration with Honeybee Robotics, Texas A&M University, and the University of Central Florida," according to a recent company post. "And we just wrapped up our initial research, proving the solution is feasible in the lunar environment."

Masten has been busy thinking up innovative concepts to commercialize lunar travel. The company recently unveiled its GPS concept for the moon, and it's working on ways to extract water using lander engines -- ironically, a process that would intentionally displace significant volumes of regolith.

For the current test, Masten figured out the thickness required for the pads to work effectively.

As an example, a large-scale Artemis human landing system would require alumina particles of approximately 0.5 millimeters diameter to pass through the engine without melting. The particles would impact the lunar surface at approximately 1,500 meters per second to create an initial base layer on the lunar surface that's approximately 1 millimeter thick.

After the base layer is deposited, alumina particles of approximately 0.024 millimeters in diameter would be required to heat up and liquify as they pass through the engine. These particles would impact the surface at approximately 650 meters per second and create additional layers that build up and strengthen the landing pad. The full deployment would take 10 seconds to release 186 kilograms of alumina at up to 30 meters above the lunar surface, creating a 6-meter diameter landing pad. The pad would then require 2.5 seconds to cool before the vehicle touches down for a safe landing.

If that kind of calculation doesn't make the engineering problem solver in you light up, it's time for a vacation and a recharge. Space is once again home to some of the most creative engineering and applied chemistry in the world, thanks to the burgeoning commercial space sector.

The solution is still a long way from implementation, but Masten has big plans for the moon and beyond. The company is also ambitiously turning its sights on Mars.

"In Phase I, we advanced the technology readiness and laid the groundwork for future development. Our goal is to further mature the landing pad technology by testing it in a lunar environment in the next phase. Looking even further ahead, the FAST concept can be applied to other planetary bodies like Mars where loose regolith also poses risks to human and robotic missions."

Tags quentes :

Inovação

Espaço

Tags quentes :

Inovação

Espaço